The C-41 Process: An Intro to Film Development Essentials

The C-41 process has been the most widely used technique for developing color films since its introduction by Kodak in 1972. This chromogenic color print film development process replaced the older C-22 method, and today it's known by different names such as CN-16 by Fuji, CNK-4 by Konica, and AP-70 by AGFA. Its popularity can be attributed to its compatibility with most modern color films and photofinishing labs.

Throughout our article, we will help you gain a comprehensive understanding of the C-41 process and its importance in the world of film photography. From the necessary equipment and materials to detailed steps and common issues that may arise, we aim to provide a thorough guide for anyone looking to learn more about this staple of film development.

Key Takeaways

- The C-41 process is a popular method for developing color films used by both amateurs and professionals.

- A basic understanding of the equipment and materials required for the process is essential for successful results.

- Awareness of common issues and their solutions ensures optimal outcomes in both commercial and individual settings.

Understanding C-41 Process and Its Importance

C-41 vs CN-16 and CNK-4

The C-41 process, introduced by Kodak in 1972, is a chromogenic color print film developing process. It supersedes the older C-22 process, offering better image quality and consistency. Its popularity led to the creation of similar processes such as CN-16 by Fuji and CNK-4 by Konica.

Chromogenic color film development is essential for photographers wanting to capture vibrant color images with an analog medium. These processes differ slightly in their steps and chemicals used, but they all yield stunning results when done properly.

Historical and Modern Use

The C-41 process has been vital in the evolution of color film photography since its inception. It changed the game by providing a more streamlined and convenient approach to developing color negatives. Historically, it not only facilitated professional photography but also enabled enthusiasts to experiment with film.

In modern times, despite the rise of digital photography, there is still a significant number of photographers who appreciate the artistry, craftsmanship, and unique look of analog photography. The C-41 process remains relevant and continues to be used by professional labs and home developers alike.

In conclusion, understanding the C-41 process and its importance in both historical and modern contexts allows us to appreciate the beauty and legacy of color film photography. By learning about its various aspects, we can enhance our skills and capture stunning images that stand the test of time.

Necessary Equipment and Materials

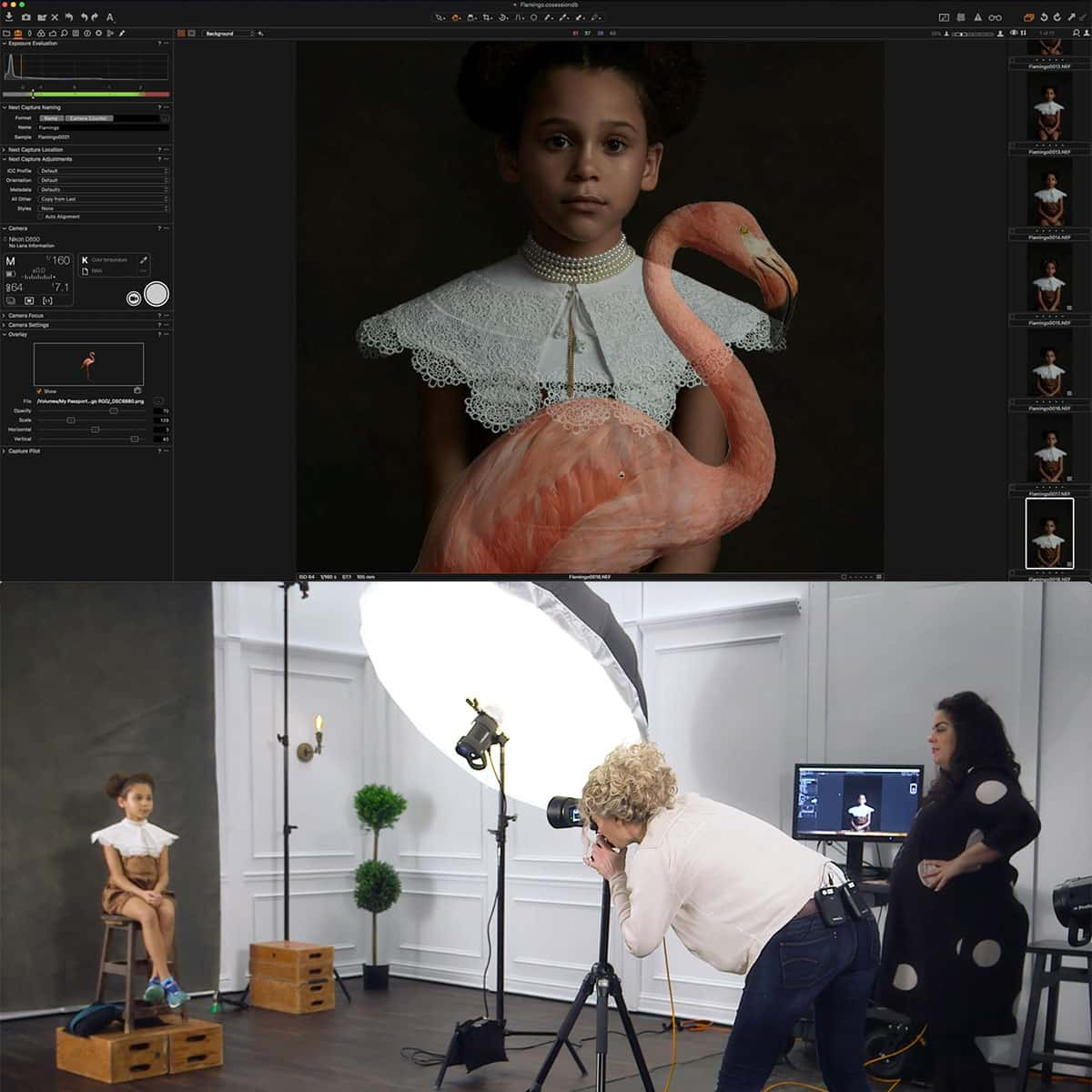

Choosing Quality Equipment

When it comes to the C-41 film development process, having the right equipment is crucial. We highly recommend using a reliable developing tank, as these containers are specifically designed for film processing. A high-quality thermometer is also essential, as precise temperature control is critical to the success of the process.

Apart from the developing tank and thermometer, a changing bag is another useful piece of equipment. This light-tight bag allows us to load the film onto a reel and into the developing tank without exposing it to light, which is especially helpful if we don't have access to a completely dark room.

Chemical Handling Precautions

Handling chemicals safely and accurately is vital to achieve consistent results with the C-41 process. Here is a list of basic precautions we should take while handling chemicals for film development:

- Wear protective gloves and eyewear

- Use dedicated glassware and measuring tools

- Label chemical containers clearly

- Follow provided guidelines for mixing and timing

- Store chemicals in a cool and dark place, away from children and pets

In addition to these precautions, we should also maintain a clean and organized workspace, set up proper ventilation, and dispose of chemicals responsibly according to local regulations. By following these guidelines, we can ensure a smooth and successful C-41 film development process.

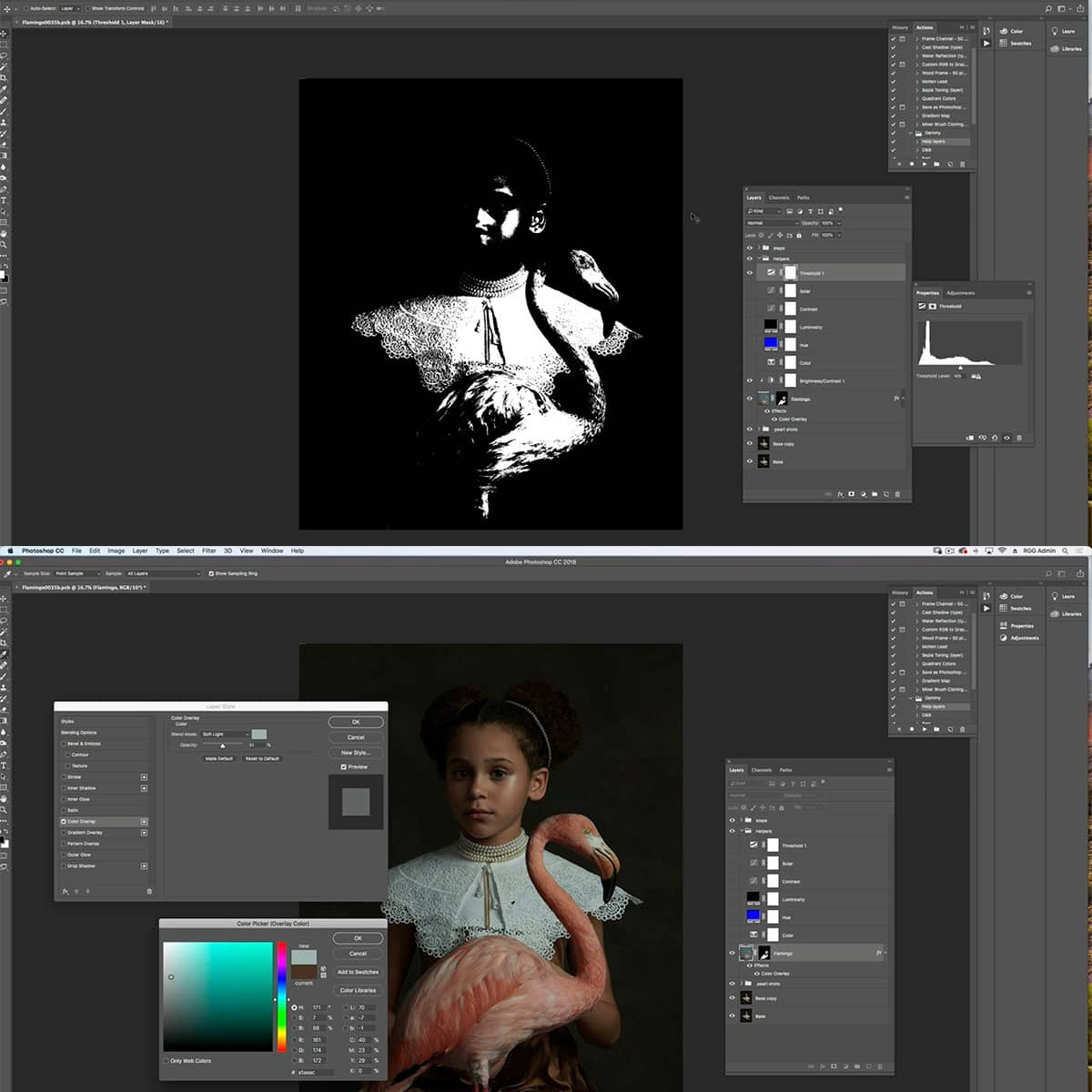

Detailed Steps in C-41 Process

Temperature Regulation

The first step in the C-41 process is pre-soaking the film in a water bath at 35 degrees Celsius (about 95 degrees Fahrenheit) to achieve a consistent temperature throughout the process1. This temperature regulation is critical, as it greatly affects the chemical reactions taking place during development.

Following the pre-soak, we mix the chemicals, ensuring each is at the correct temperature before proceeding. The developer2 and bleach3 are particularly temperature-sensitive, so do pay special attention to their temperature requirements.

Timing and Agitation Techniques

For the timing aspect of the process, we must adhere to each chemical's specific required duration. A typical C-41 process consists of several steps: development, bleaching, washing, and stabilization3. Proper timing ensures that the images come out correctly.

When it comes to agitation techniques, they differ based on the equipment being used. However, the goal remains the same across all methods: to constantly and evenly distribute the chemicals over the film. For example, one common agitation method is to invert the development tank for the first 30 seconds, followed by 10 seconds every minute thereafter4. This technique keeps the entire emulsion in contact with fresh chemicals, which is crucial for even development.

Overall, by carefully adhering to temperature regulation, proper timing, and effective agitation techniques, we ensure consistent and successful results using the C-41 process. Remember to always follow the specific instructions provided by the chemicals and development equipment being used.

Common Issues and Their Solutions

Preventing Fading

Fading is a common issue encountered during the C-41 film development process. One way to prevent fading is to maintain a constant temperature throughout the process, ideally at 38°C. To achieve this, we recommend using a temperature-controlled water bath or an accurate thermometer.

Another tip for preventing fading is to use a stop bath after the developer stage. This isn't mentioned in many instruction manuals, but it is crucial for ensuring a C-41 developing kit's longevity, as mentioned on learnfilm.photography. Using a water rinse before the blix step also helps maintain the solution and extend its life.

Handling Color Shifts

Color shifts can occur during the C-41 process, resulting in inaccurate or undesirable color reproduction. One method to avoid color shifts is to maintain proper temperature control during development, as mentioned earlier. It is crucial that the process's temperature be maintained, from the pre-soak stage to the final stage. This helps ensure consistent results and minimizes color shifts in the final images.

Inspecting and adjusting your chemicals can also help prevent color shifts. Over time, some chemicals may become unstable, leading to color shifts during development. We recommend following the guidance of Olympus Life Science and ensuring that your chemicals are in good condition and stored properly.

Finally, accurate timing during each stage of the C-41 process is crucial for preventing color shifts. Carefully follow the manufacturer's instructions and use a reliable timer to ensure that the film is not under- or over-developed.

Looking at C-41 Process in the Commercial World

The C-41 process, introduced by Kodak in 1972, has become the most popular film development process in the world. It has been adopted by other major film manufacturers, such as Fuji, Konica, and Agfa, to ensure the consistency and quality of developed photos.

Nowadays, almost all photofinishing labs process C-41 film, making it easy for photographers to find establishments that can handle their color negative film. One of the advantages of the C-41 process is that it's compatible with CN-16 by Fuji, CNK-4 by Konica, and AP-70 by AGFA, which translates to a wider range of film types being accepted by commercial development labs.

There are also various home development kits available for photographers looking to process their film themselves. Companies like Tetenal have developed kits that simplify the C-41 process, allowing hobbyists to achieve professional-quality results in their own darkrooms.

Overall, the pervasiveness of the C-41 process in the commercial world has made it more accessible to photographers, regardless of their level of expertise or the film type they work with. With multiple options for development—be it through commercial labs or at-home processing kits—color film photography remains a popular and highly achievable art form.

Frequently Asked Questions

What are the steps involved in C-41 film development?

C-41 film development involves a few crucial steps, including pre-soaking the film, adding the developer, and using the blix and stabilizer solutions. Pre-soaking helps to bring the film and developing tank to the required temperature (around 35°C) before adding chemicals. The C-41 process is temperature-sensitive, making this step essential for accurate results.

How does C-41 differ from E6 and ECN2 processes?

While C-41 is a chromogenic color print film process, E6 is used for color reversal or slide films and ECN2 for motion picture films. Each process has its chemical makeup and processing times. C-41 is the most widely used, primarily for color negative films, whereas E6 creates positive transparencies and ECN2 serves motion picture film production.

What chemicals are needed for the C-41 process?

The primary chemicals required for C-41 are the developer, blix (a combination of bleach and fixer), and stabilizer. Each chemical plays a specific role in the development of color film. For example, the developer brings out the latent image on the film, while blix removes the remaining silver halides and stabilizer ensures the long-lasting quality of the film. You can find commercial C-41 kits like the Tetenal C41 kit for home use.

Can C-41 process be used for black and white films?

Although C-41 is designed for color films, it is possible to develop black-and-white films using the C-41 process. However, the resulting images may look different than those developed in a dedicated black-and-white developer. Additionally, some C-41-compatible black-and-white films are available, specifically formulated for this purpose.

What is the standard developing time for C-41 films?

The standard developing time for C-41 films varies based on the specific film and developer used. However, generally, it takes around 3 minutes and 15 seconds at 38°C (100°F) for most films. It's essential to follow the instructions provided with the developer or film to achieve the best results, taking into account the chemical concentrations, film type, and required development temperature.

How can I identify if a film is suitable for C-41 processing?

Most color negative films are designed for C-41 processing, and this information will usually be indicated on the film canister or packaging. Look for labels like "C-41 compatible" or a reference to this process. If in doubt, it's best to consult the film's user guide or contact the manufacturer before attempting C-41 development to ensure the film's compatibility and optimal image quality.